Scope of Work

Control Equipment.

- Test the electrical system for safety and correct operation.

- Check blowers and control equipment for correct function and replace consumable parts as required.

- Check air flow and pressure readings for each blower unit against the schedule to ensure the performance is within the specified limits. Investigate and repair as required using all necessary spare parts. Re-test upon completion and record.

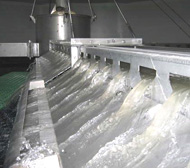

Biotec Unit

- Inspect the Biotec superstructure and check that it is sound and watertight. Check all manhole covers are correctly fitted and are in good condition.

- Check all internal fittings are correctly positioned and securely fixed.

Distribution.

- Remove any excess sludge and debris from the distributor. Inspect media guard for debris, replace as required.

- Monitor distributor efficiency and ensure the effluent is being applied correctly across the media surface.

- Inspect filter media for signs of blockage.

- Check Biomass growth on media surface and observe the health of film growth. Remove any non biological solids from the media.

General

- Monitor primary sludge build-up. Note sludge condition and advise when emptying is required.

- Monitor build-up and condition of humus sludges within the Biozone and final zone. Advise if emptying is required.

- Monitor hydraulic levels within the plant and note any signs of surcharging or level imbalance within the system.

- Locate and inspect final effluent out-fall or connection to Soakaway system. Observe quality of final effluent and look for signs of overloading. Note clarity, colour and odour.

- Sample final effluent, if requested to do so.

NOTE: cost of analytical report will be charged for as an extra.

Biotec Integral Pump sets (where fitted)

Single Pump System

- Check that pump well is sound and watertight and that chamber access cover is in good condition and fitted correctly.

- Raise the pump from its base, remove any sludges and debris from the inlet strainer and flush clean. Carry out inspection and servicing of pump in accordance with the manufacturers procedures. Re-install the pump and carry out functional tests.

- Check the correct operation of the float switches, electrical control equipment and alarm systems, where fitted. Adjust and re-check as necessary.

- Observe sludge build-up in the pump chamber and advise when removal is necessary.

- Monitor pump discharge in relation to the incoming flow. Note any signs of high liquid level in chamber which might indicate inadequate performance or restricted discharge.

Dual Manual Pump System

- Repeat checks detailed above for second pump. Ensure that the pumps are positioned correctly within the chamber to prevent interference with level control.

Dual Automatic Pump System.

- Repeat all checks, detailed above for single and dual automatic systems.

- Simulate automatic operational control sequences and ensure correct automatic functioning of all equipment.

Dependent upon the individual installations any additional equipment which requires servicing will be serviced in accordance with the manufacturers specific instructions. If this equipment was not initially covered by the Contract additional labour will be noted and charged for accordingly.

When the pump(s) require major overhaul the replacement cost will be compared with that for factory repairs and or replacement units, you will be advised of the best course of action.

Reports

On completion of service visit, a job sheet detailing the checks carried out and listing replacement parts used will be completed and a copy made available for the customer. This job sheet will indicate any areas requiring attention. Should the customer be out at the time of service our engineer will initial the sheet and leave you a copy. If additional work is required this will be communicated in writing.